About Cancade CBI Ltd.

CANCADE CBI Limited, based in Brandon, Manitoba, Canada, is a multi-dimensional manufacturing company, offering advanced welding and component development in addition to our award winning line-up of trucks, trailers and agricultural equipment.

Operating for over 95 years, the Cancade CBI Limited manufacturing facility has the unique combination of fabrication and machining capabilities to provide customers with large complex finished components and assemblies.

We safely do what we say, when we say. Our reputation in the industry is based on honesty and integrity. Our customers know they will receive high quality components delivered on-time.

Cancade CBI Limited “Finding a Better Way!”

About the Cancade CBI Team

- ISO 9001-2015 Certification

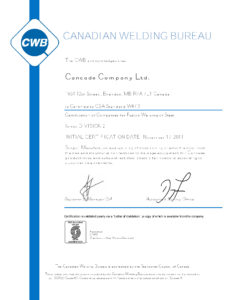

- CWB Certification to weld in accordance with procedures set forth by CSA, AWS and ASME.

- Total manufacturing footprint of approximately 75 K square feet.

- A dynamic management team diversified in skill sets, with solid analytic skills, experience in strategic planning, and trusted business acumen.

- Sophisticated engineering support.

- Talented and skilled labour team, led by dedicated and seasoned project managers.

- Experienced and proven technical sales and support team.

- Dedicated marketing resources.

- Significant capacity and capability expansion plans to complement our aggressive growth targets.

- A decidedly open and transparent business communication methodology based on respect and trust.

- Cancade CBI Limited is a Theory of Constraints company, utilizing key elements of Lean Manufacturing.

Advantages of Partnering with Cancade CBI Company

- Logistics; the Cancade CBI Limited manufacturing facilities are located in the geological center of North America.

- Experience; Cancade CBI Limited has been operating for 95 years.

- Reputation; a trusted and well-known company, Cancade CBI Limited has a solid name in the manufacturing sector.

- Value; Cancade CBI Limited maintains a stable labour force and a cost overhead that ranks among the lowest rates in Canada.

- Flexibility; utilizing three locations, company owned transportation, engineering resources, numerous lift and rigging options, machining, fabricating, welding, cutting, assembly and blast/paint & powder coating departments, Cancade CBI Limited can configure our operations to accommodate a wide variety of specialized manufacturing activities.

- Quality; strict adherence to advanced procedures and policies, Cancade CBI Limited is committed to providing exceptional quality and dependability.

- Integrity; Cancade CBI Limited safely does what we say, when we say. Communication is based on honesty and transparency; our customers know they will receive components of the highest quality delivered on time.

Facility & Equipment

- Approximately 75K square feet- Total Manufacturing Footprint

- Overhead Cranes, Jibs, and expansive rigging options

- Industrial Duty Weld Tables for large scale fixturing projects

- Full Steel, Aluminum and Tig Welding Cells

- Truck and Trailer Body Manufacturing

- Trailer Chassis Manufacturing

- Custom Weldment Manufacturing

- Custom Assembly, Kitting

- 8K square feet- Heavy Duty Truck and Trailer Service Area

- Truck Body and Hoist Specialists

- Power Take-Off and Hydraulic Specialists

- Power Tailgate Specialists

- Van Body Sales, Service and Installations

- Manitoba Heavy Truck and Trailer Safety Inspection Center

- Frame Modification and Repair Cell

Fabrication & Machining

- Hydmech Automatic Saw – Model S-20A

- Hydmech Semi-Automatic Saw – Model S-20P

- Scotchman Iron Worker – Model 9075-12

- Mubea Iron Worker – Model KBL13

- 33’ Cincinatti 400 Ton Mechanical Brake with electric CNC Controls

- 20’ Pearson Shear – Model 6113

- 10’ Accupress Press Brake – Model 7025012

- 6’ – 25 Ton Chicago Press Brake – Model 265 SPL

- Gisholt No3 Turret Lathe

- DMTG CNC Lathe – Model CKE61502

- TOS Lathe

- 24’ x 10’ Koike High Definition Watertable CNC Plasma

- 24′ x 10′ Machitech Diamond Cut Downdraft CNC Plasma Table

- TOS 4″ Horizontal Boring Mill

- Comet CNC Bed Mill

Sandblasting & Painting

- 16’W x 59’L x 10.5’H End Draft Paint Booth

- Multiple Spray Systems

- Custom Color Matching and UTEC Mixing Station

- 64’ x 30’ Indoor Sandblasting Facility – Silica and Star Blast

- Star Blast Reclaimer/Recycler

- 40 Ton Sand Silo

- Kaiser Twin Air Compressor System – 50HP and 40HP

- Powdercoating

Welding

- Plasma Transfer Arc (PTAW) Precision Robotic Welding

- H.V.O.F. High Velocity Oxygen Fuel Thermal Spray Process

- Lincoln Precision Tig 375 Tig Welder (Aluminum, Stainless)

- Miller Syncrowave 350 Tig Welder (Aluminum, Stainless)

- Motoman Dual-Head Robotic Weld System

- Approximately 25 Lincoln Mig Welders

- Approximately 6 Miller/Hypertherm Plasma Cutters

- Member of Canadian Welding Bureau (CWB) QualityMark program.